PDF) A Mathematical Dimensional Model for Predicting Bulk Density of Inconel 718 Parts Produced by Selective Laser Melting

Materials | Free Full-Text | Laser Polishing of Additive Manufactured 316L Stainless Steel Synthesized by Selective Laser Melting | HTML

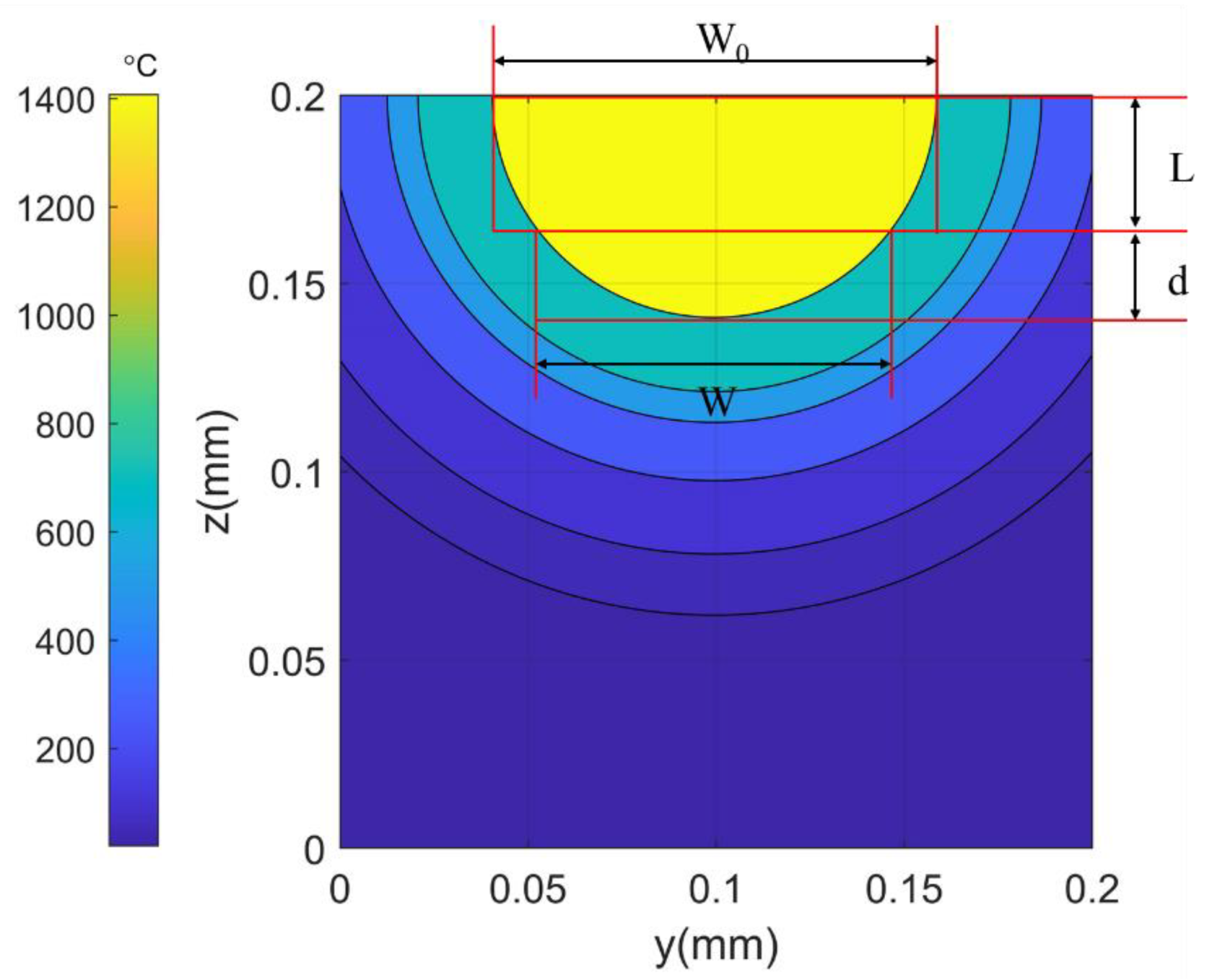

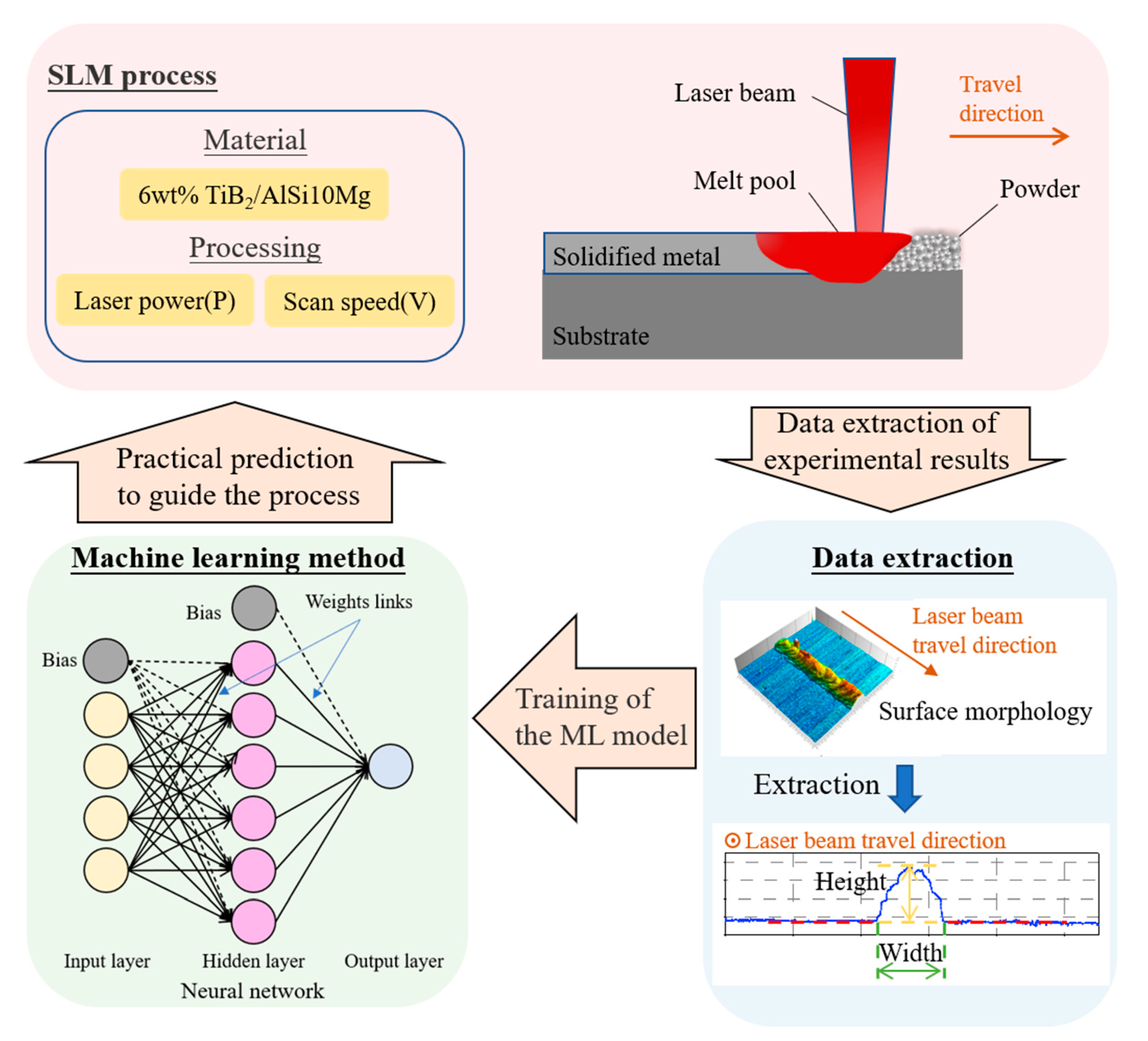

Materials | Free Full-Text | Predicting the Printability in Selective Laser Melting with a Supervised Machine Learning Method | HTML

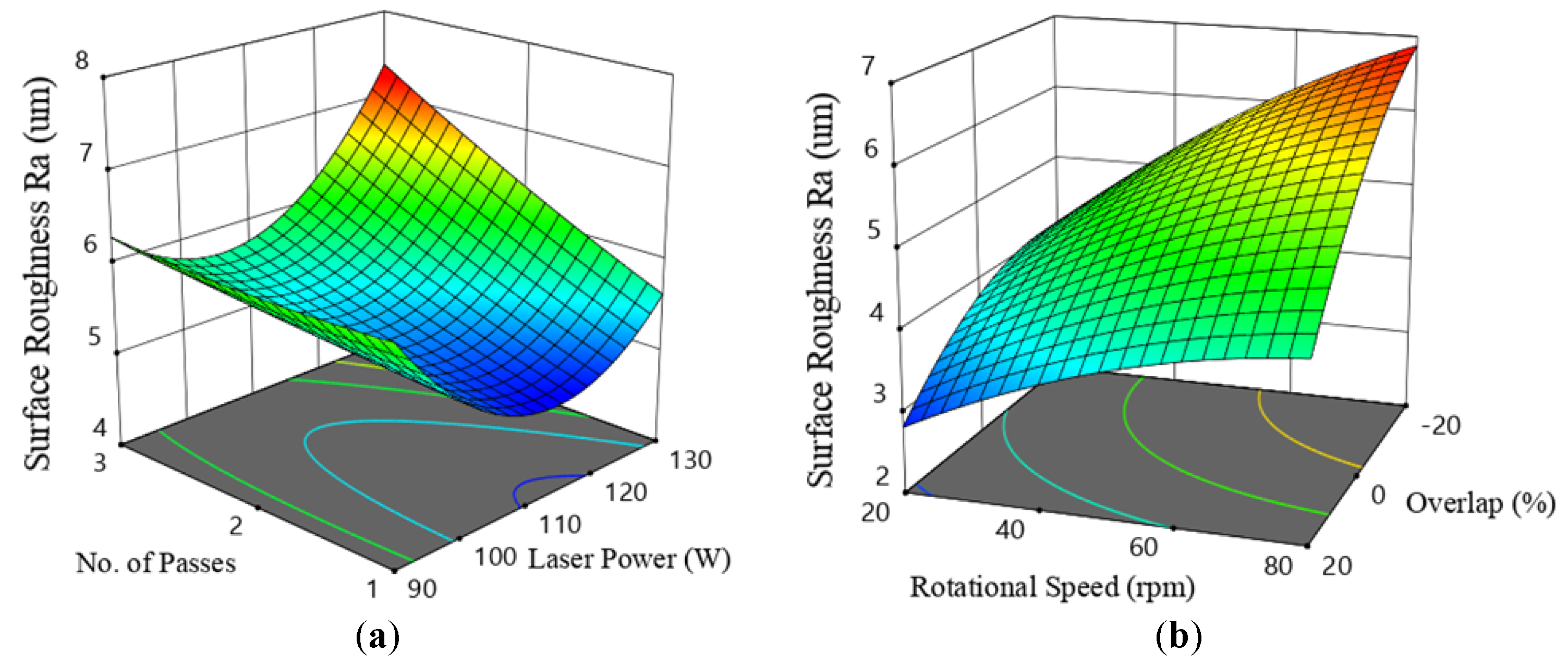

Materials | Free Full-Text | Research and Optimization of Surface Roughness in Milling of SLM Semi-Finished Parts Manufactured by Using the Different Laser Scanning Speed | HTML

How build angle and post-processing impact roughness and corrosion of additively manufactured 316L stainless steel | npj Materials Degradation

Surface roughness Ra prediction in Selective Laser Melting of 316L stainless steel by means of artificial intelligence inference - ScienceDirect

Hyperspectral imaging for prediction of surface roughness in laser powder bed fusion | springerprofessional.de

Surface roughness Ra prediction in Selective Laser Melting of 316L stainless steel by means of artificial intelligence inference - ScienceDirect

Dependence of average surface roughness Ra on powder layer thickness.... | Download Scientific Diagram

Experimental and numerical assessment of surface roughness for Ti6Al4V lattice elements in selective laser melting | SpringerLink

PDF) Surface Texture Characterization of Metal Selective Laser Melted Part With Varying Surface Inclinations